Introduction

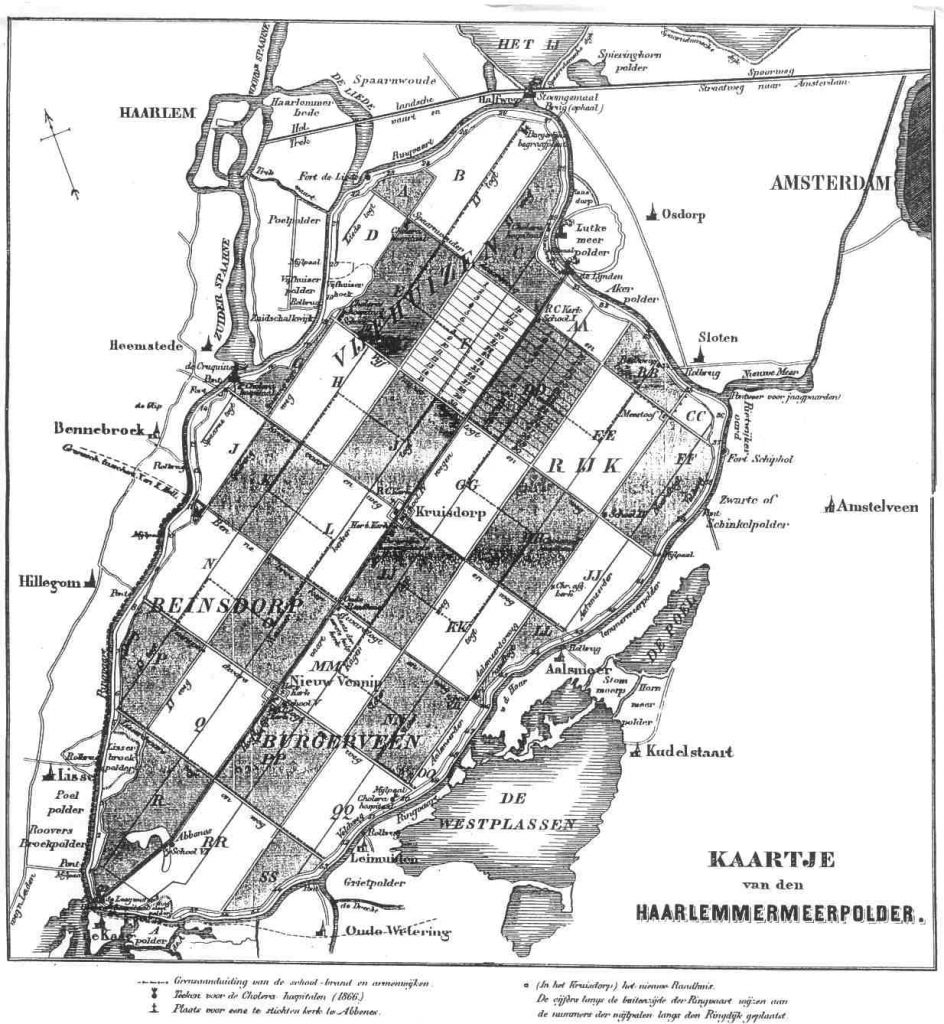

Without enclosure and drainage, more than half of the area of the present-day Netherlands would be flooded with every high tide, every wet season, or permanently. The struggle for the country’s survival has largely determined its appearance and left numerous marks on it. In the triangle between the cities of Amsterdam, Haarlem and Leiden the 45000 acre Haarlemmermeer polder demonstrates an extraordinary step in the scale of land drainage. After centuries of preliminaries, a lake of unprecedented size was drained in three years (1849- 1852) and transformed into valuable agricultural land. The work was done by three huge steam pumping stations. Steam power had been used for drainage in Holland before, but only on a smaller scale.

The early history of polder drainage

The earliest polders were formed by enclosing a piece of foreshore by a dike with a sluice gate, which was opened at low tide. Subsidence upon drying of the polder floor made power drainage inevitable. This also allowed stricter control of the water level.

As technology developed, draining lakes to create polders became feasible. A system for controlling the water-table developed, with polders discharging into rivers or the sea via one or more intermediate collecting basins called `boezems´ in Holland. Large boezem-capacity – buffer storage – meant less dependency on immediate discharge, and so the polder authorities favored a large boezem/polder area ratio. A man with a bucket could lift about 33 000 gallons of water one foot high in a day, developing an average power of about 0.02 hp. There were not enough animals to power pumps, and water power was not available in these low lands. Power drainage was severely limited until the advent of the windmill-driven scoop wheel in the early 15th century. The lift of a reasonably-sized scoop wheel is 3-6 ft. In the early 17th century higher lifts were achieved by cascading two or more scoop wheels. Not long afterwards the Archimedean screw appeared, allowing lifts of 12-15 ft in a single stage.

In 1787 a first Boulton & Watt steam pump was built for drainage purposes near Rotterdam. This met with success, but acceptance of steam power was slow in Holland. Land drainage required maximum security, with emphasis on reliability, and so the established technology of wind power remained long in favor. Steam power was considered less reliable, and more costly in terms of capital outlay, fuel, and skilled personnel.

Haarlemmermeer

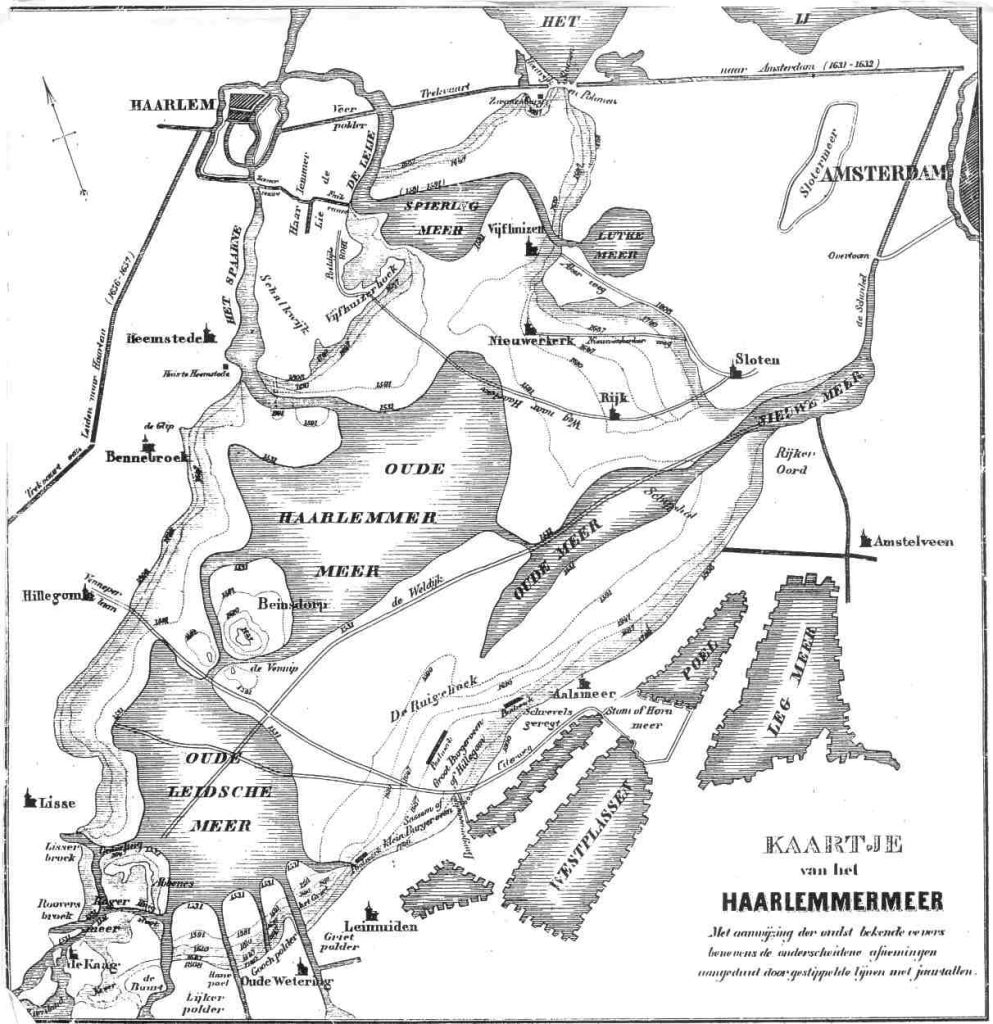

In medieval times there were numerous lakes in the peaty land between Amsterdam, Haarlem and Leiden. As a result of erosion and peat digging, several of these lakes merged to form the Haarlemmermeer (Haarlem Lake). In the late 16th century, this growing inland sea became a threat. But, it was also useful to the nearby towns for shipping and fishing, and for draining sewage. Over the next two centuries more than 200 schemes for partial or complete drainage of the lake were proposed. Due to conflicting interests, jealous local administrations, and high cost none of these schemes came to anything. However over the years increasing amounts had to be spent on building and maintaining structures to reinforce the banks. In the long run these were not satisfactory solutions for control of such a vast expanse of water.

Drainage by steam

In the 19th century government became centralized, gained real power and became capable of enterprises on a national scale. Two heavy storms in 1836 drove home the continuing menace of the `water wolf´. King Willem I appointed a committee to draw up proposals for draining the Haarlemmermeer at very short notice. The report called for drainage by 79 large windmills with Archimedean screws and scoop wheels, supplemented by three small steam-powered Archimedean screws.

The King was not satisfied, and he ordered a closer look at the feasibility of steam-powered drainage. A second committee was formed, but internal disagreement on drainage by wind or steam resulted in deadlock. In 1840 renewed government intervention finally resulted in a report with clear recommendations, and soon the decision to use steam power alone was taken. This was a bold step: steam power had never been used on this scale before, and earlier applications on a smaller scale had met with mixed success. There was also reluctance to experiment with such an important provision as polder drainage. In addition, expensive coal would have to be imported, unless peat could be used (but experiments with that failed).

A visit to Cornwall had convinced the committee of the reliability and efficiency of the Cornish pumping engine. This type of engine was used for pumping relatively small quantities of water out of deep mines. To make them suitable for land drainage, i.e. large quantities at relatively low lift, considerable adaptation of the standard design would be required. In addition, the proposed scale of the three pumping stations exceeded anything previously built. One of the three stations, Leeghwater, was built and tested first to make the risks more manageable. This caused some delay, but it permitted design adjustments for the remaining two: Lynden and Cruquius.

And later…?

The initial drainage took from 1849 to 1852. All three pumping stations worked continually at maximum capacity, with a few interruptions. Later they kept the polder dry, and were idle during long periods. As agricultural needs changed, the water-table had to be kept within stricter limits, with shorter, intenser pumping periods. It turned out that Cruquius, even with more boilers, could power only seven pumps at full lift, so one pump remained permanently disconnected.

The other pumping stations, Leeghwater and Lynden, were modernized over the years, and have provided the polder’s drainage to this day. After a period on stand-by Cruquius finally became redundant in 1932. An initiative was taken by the Koninklijk lnstituut van Ingenieurs to preserve it. In 1933 Cruquius became one of the first industrial monuments in the Netherlands, and even of the world. The engine and pumps of Cruquius were never modernized or modified, nor was the building, after early extensions to the boiler house. After 1932 the boilers were removed and scrapped. Otherwise the drainage station is just as it was built in 1846-1849.

International Landmark

The American Society of Mechanical Engineers (ASME) designated the Cruquius steam drainage pumping station the 33rd International Historic Mechanical Engineering Landmark in 1991.

The ASME Landmarks Program recognizes our technological heritage and serves to encourage the preservation of the physical remains of historically important works.